Development and Innovation of PCB technology

With the rapid development of electronic technology, only by recognizing the development trend of PCB technology can circuit board manufacturers actively develop innovative production technologies to find a way out in the highly competitive PCB industry.

1. Develop component embedding technology

Component embedding technology is a huge change in PCB functional integrated circuits. It forms semiconductor devices (active components), electronic components (passive components) or passive components on the inner layer of the PCB with the function "component embedded PCB" and has begun mass production. However, in order to develop circuit board manufacturers, analog design methods must first be addressed. Production technology, inspection quality, and reliability assurance are also top priorities.

2. HDI technology is still the mainstream development direction

HDI technology promoted the development of mobile phones, promoted the development of information processing and basic frequency control functions of LSI and CSP chips, as well as the development of template substrates for circuit board packaging, and also promoted the development of PCBs. As HDI embodies the most advanced technology of contemporary PCB, which brings fine wire and tiny aperture to PCB boards. HDI multi-layer board application terminal electronic product-mobile phone is a model of HDI cutting-edge development technology.

3. Continuously introduce advanced production and update circuit board production technology

HDI circuit board manufacturing has matured and become more and more perfect. With the development of PCB technology, although the commonly used subtractive manufacturing in the past still dominates, low-cost processes such as additive and semi-additive methods have begun to emerge. The use of nanotechnology to make holes metallized while forming PCB conductive patterns. New flexible manufacturing process method, inkjet PCB process, high reliability, high quality printing method. Production of fine wires, new high-resolution photomasks and exposure equipment, and laser direct exposure equipment.

4. Develop higher performance PCB raw materials

Whether it is rigid PCB or flexible PCB materials, with the globalization of lead-free electronic products, these materials must become more heat-resistant. Thus, new materials with high Tg, low thermal expansion coefficient, low dielectric constant, and excellent dielectric loss tangent are emerging.

5. Optoelectronic PCB has a bright future

The photoelectric PCB circuit board uses the optical path layer and the circuit layer to transmit signals. The key to this new technology is to manufacture the optical path layer. It is an organic polymer, formed by methods such as photolithography, laser ablation, and reactive ion etching. As a major producer, Chinese circuit board manufacturers should also actively respond to and keep up with the pace of scientific and technological development.

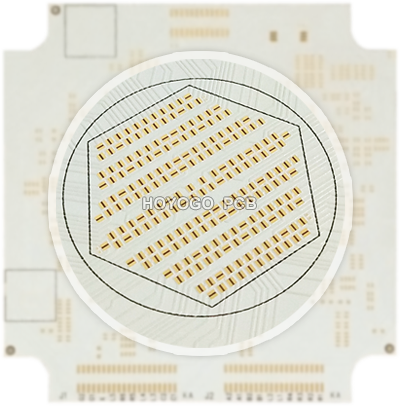

SHENZHEN HOYOGO ELECTRONIC TECHNOLOGY CO., LTD. is an international, professional, reliable PCB manufacturer. We have 2 production bases with a monthly production capacity of 500,000 square meters. One-stop PCB product supply and solution. And HOYOGO have a management team with 25 years of average industry experience and reliable quality assurance.

评论

发表评论