What is the Effect of Humid Environment on PCBA

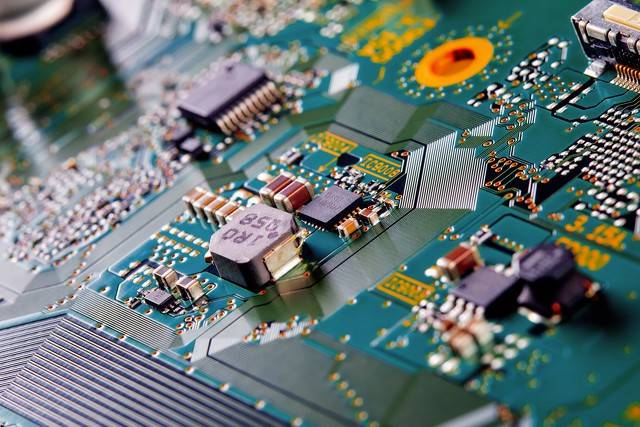

There is a lot of moisture in the air, when the humidity is too high, it will turn into water droplets and fall on the PCB board and electronic components. So what kind of effect does this humid environment have on PCBA?

In the process of PCBA processing, it is necessary to ensure the humidity balance in the workshop, so that the humidity value is within a suitable range. If the humidity is too low, the air will be too dry, which not only easy to generate static electricity, but also to accumulate dust. If the humidity is too high, it is easy to cause the PCBA to be damp and oxidized or to burst.

Before PCBA processing, if the electronic components are damp, the pins of the electronic components will be oxidized, or there will be undesirable phenomena such as tin rejection and fried tin during the welding process. And if the PCB board is exposed to a high humidity environment for a long time, it will cause the board surface to be damp, and it is easy to burst the board during processing.

So how to prevent moisture? PCBA can be used to prevent moisture by coating with conformal paint and vacuum packaging, and can also improve the PCBA storage date. If the PCB board and electronic components are damp due to improper storage, it can be baked in advance before use to evaporate the moisture to prevent moisture.

SHENZHEN HOYOGO ELECTRONIC TECHNOLOGY CO., LTD. is a company specializing in providing overall PCBA electronic manufacturing services, including one-stop services from upstream electronic components procurement to PCB production and processing, SMT patch, DIP plug-in, PCBA testing, and finished product assembly.

评论

发表评论