Requirements for SMT processing on SMT adhesive

In SMT processing, SMT adhesive is one of the important production raw materials. Before wave soldering, the PCBA factory needs to use SMT adhesive to fix the mounted components on the corresponding position of the PCB, so as to prevent the components from falling into the tin pot during wave soldering. So what are the requirements for SMT adhesives in SMT processing?

1. The service life is longer at room temperature.

2. Suitable viscosity.

The viscosity of the SMT adhesive should be able to meet the needs of different sizing methods, different equipment, and different sizing temperatures. There should be no wire drawing when dispensing glue. It can maintain enough height after coating without forming too much rubber base. After coating and before curing, the drips should not flow, so as not to reach the welding part and affect the welding quality.

3. Fast curing.

The SMT adhesive should be cured at the fastest speed at the lowest possible temperature. This can avoid PCB warpage and damage to components, and also avoid pad oxidation.

4. Adhesive strength should be appropriate.

The SMT adhesive should be able to effectively fix chip components before welding, and it should be easy to replace unqualified components during maintenance. The shear strength of SMT adhesive is usually 6~10 MPa.

5. Other. For example:

1) There should be no outgassing after curing and during welding;

2) It should be compatible with the chemical agents in the subsequent process without chemical reaction;

3) Do not interfere with circuit function;

4) Because of the color, so easy to check;

5) Typical colors for SMT adhesives are red or orange.

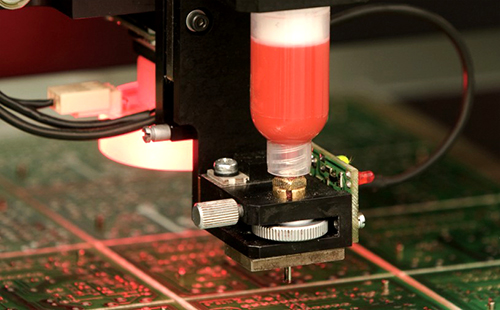

6. Packaging of SMT adhesive.

At present, there are two main types of packaging for SMT adhesives on the market. One is the syringe-type packaging, which can be used directly on the dispensing machine. Its packaging specifications mainly include 5ml, 10ml, 20ml and 30ml. In addition, there is a large package of 300ml injection tubes, which are divided into small needle tubes and then put on the dispensing machine when used. Please note that special tools should be used for dispensing large packages into small syringes.

HoYoGo is an international, professional and reliable PCBA factory. We not only have our own factory, but also has many years of experience in SMT processing. We can provide you with professional SMT processing services, and accept customers’ materials processing and OEM and other processing forms.

评论

发表评论