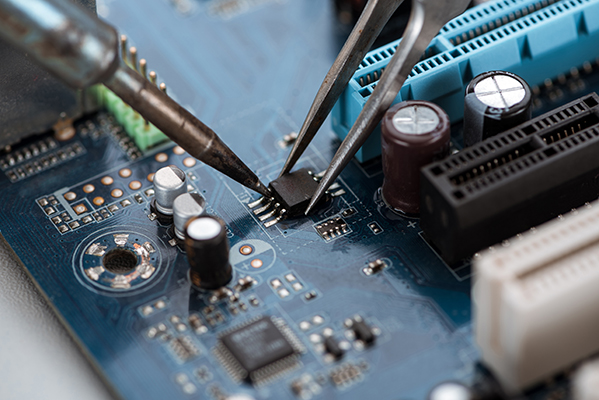

The Role of Soldering Flux in SMT Processing

In the process of SMT welding processing, soldering flux is often used, so what is the effect of using soldering flux?

1. Remove oxide

The Abietic Acid in the soldering flux can have a reduction reaction with the oxide film on the surface of the welded metal to generate Copper Abietate, which can remove oxides or other dirt on the soldering surface.

2. Prevent secondary oxidation

During SMT welding processing, the soldering flux will cover the surface of the welded metal and solder, which can isolate it from the air and prevent the secondary oxidation of the solder.

3. Reduce solder tension

When the soldering flux removes the oxide on the soldering surface, a certain chemical reaction occurs, which can reduce the surface tension and viscosity of the solder, while increasing the surface activity, thereby improving the wettability of the solder.

4. Better heat transfer

The soldering flux reduces the surface tension and viscosity of the solder, and also increases the fluidity of the liquid solder, which is conducive to the rapid and effective transfer of heat to the soldering area.

5. Protect soldering materials

In the process of SMT processing and welding, the original surface protective layer of the welded material will be destroyed. A good soldering flux can quickly recover to protect the welding materials after welding.

In summary , it is very important to use soldering flux in the process of SMT soldering.

评论

发表评论