What Should be Paid Attention to in the Multilayer PCB Lamination Process

What is lamination? Lamination is a forming process that combines multiple layers of the same or different materials under heat and pressure. The whole process of lamination includes Kiss pressure, full pressure and cold pressure. So what should be paid attention to during the lamination process?

1. In terms of design, the thickness, dimensions and positioning holes of the inner core board must be designed in accordance with the requirements of lamination. In general, it is required that the inner core board has no open circuit, short circuit, no oxidation, and no residual film.

2. When laminating multi-layer boards, we need to process the inner core board. The treatment process includes black oxidation treatment and browning treatment. Oxidation treatment is to form a black oxide film on the inner copper foil, and browning treatment is to form an organic film on the inner copper foil.

3. In the lamination process, we need paid attention to 3 problems: temperature, pressure and time. Regarding the temperature, we mainly pay attention to the melting temperature and curing temperature of the resin, the set temperature of the hot plate, the actual temperature of the material and the change of the heating rate. As for the pressure, the basic principle is to fill the interlayer cavity with resin and discharge the interlayer gas and volatiles. Regarding the time, mainly pay attention to the pressing time, heating time and gel time.

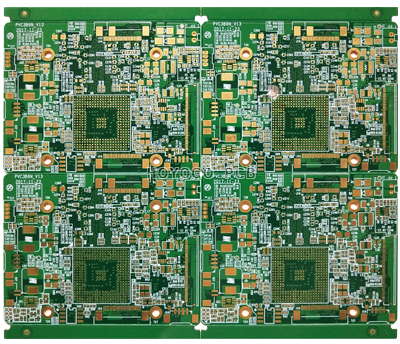

HoYoGo is an international, professional and reliable PCB manufacturer, we have our own factories, advanced machines and excellent quality system. We can provide you with competitive material prices, support various complex technologies and customize all your needs. If you have related needs, welcome to contact us!

评论

发表评论