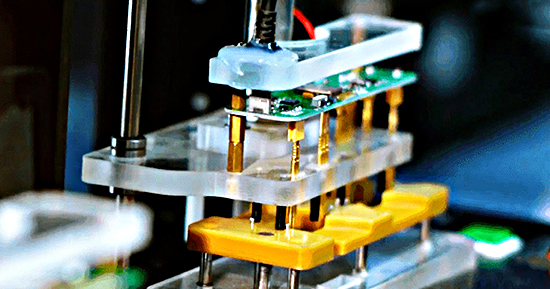

How to Strictly Control the Quality of PCBA E-test Fixtures

In electronic manufacturing field, PCBA E-test fixtures are key equipment to ensure the quality and reliability of circuit boards. It is like the meticulous inspector, holding a magnifying glass in one hand and a wrench in the other, closely inspecting each circuit board. So do you know how to strictly control the quality of PCBA E-test fixture?

1. Design and Customization of E-test fixtures

The design of the PCBA E-test fixture is like a suit tailor-made for each circuit board, ensuring that every test point can be accurately connected. Engineers thoroughly analyzed the functional requirements of the circuit board and made the E-test fixtures cover all key test points and signal paths. This custom design, like putting a custom suit on the circuit boards, allows them to pass all quality tests efficiently and elegantly.

2. Early Diagnosis and Prevention of Faults

PCBA E-test fixtures can be said to be experts in “knowing problems early”. It can detect potential problems in the early stages of production. It is like an early warning system, which can help us detect problems in advance, fix them, and prevent bad products from "mixing" into the next production link. This not only saves time but also avoids causing more trouble. In addition, the detailed fault data provided by the E-test fixtures helps the manufacturing team analyze the cause of the fault, thereby optimizing the production process and improving the overall production quality.

3. Automated Testing Improves Production Efficiency

The automation function of the PCBA E-test fixtures is like the "robot Xiao Li" in the field of electronic manufacturing, completing testing tasks quickly, continuously and accurately. Compared with traditional manual testing, it can greatly improve testing efficiency, allowing each PCBA board to pass the same standard test, greatly reducing the impact of human factors on test results. It is simply a "high-efficiency production line" in an electronics factory.

4. Guarantee of Product Consistency and Reliability

In mass production, maintaining product consistency and reliability is of paramount importance. The PCBA E-test fixtures is like a quality steward, executing strict testing procedures to ensure that each PCBA board meets uniform quality standards before leaving the factory. This not only lays a solid foundation for the reliability of the final product, but also greatly enhances the consumers' trust in the brand.

5. Flexibility and Adaptability

The design of the PCBA E-test fixtures shows extremely high flexibility and adaptability, just like the "Transformers" in the electronics factory, able to change forms at any time to adapt to the testing needs of various products. Whether it is changing the test program or adjusting the fixture, it can always respond quickly to meet the quality inspection needs of various products. This flexibility and high adaptability make it a powerful assistant in the electronics manufacturing industry.

Therefore, PCBA E-test fixtures play an important role in the field of electronic manufacturing. By using it, we can detect potential "minor problems" early and take corresponding measures in advance to make our products more "healthy"! It not only improves production efficiency, but also ensures that every product is treated "equally". It is simply the "quality nanny" of the electronics manufacturing industry! As electronic products become more and more "intelligent" and "complex", the role of PCBA E-test fixtures has become more and more "magical" and "important"!

If you are looking for a reliable PCBA service provider, when you read this article, congratulations, you have found it! HoYoGo is an international, professional and reputable PCBA manufacturer, we have our own factories, advanced machines, and experienced technicians and multiple QA personnel to strictly control every quality inspection and ensure the reliability of the quality of every product delivered to customers. So, if you have related needs, you are welcome to send us your inquiries.

评论

发表评论