The Key Points for FPC Material Selection

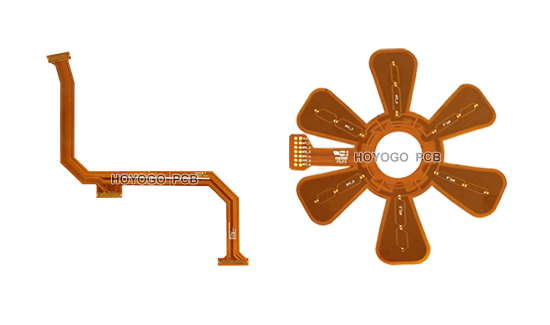

FPCs are widely used in electronic products, such as smartphones, wearable electronic devices and so on. The selection and design of materials directly affect performance and durability of the products. This article briefly introduces the key points of FPC material selection, including side keys, buttons, connecting lines, sliding covers and multilayer flexible boards, and discusses the selection criteria for auxiliary materials and conductive materials. Let's learn more about it!

1. Material Selection for Side keys/ Buttons

When purchasing side keys and main buttons, double-sided electrolytic copper with 18/12.5 specifications should be chosen (except in special cases). For bending, there are no special requirements for side keys and main buttons. They only needs to be soldered and fixed on the main board, but it must be ensured that there are no abnormalities after being bent back and forth more than 8 times before it can be used. There are strict requirements on the thickness of the key positions, which must meet the customer's total thickness requirements to ensure the key feel.

2. Material Selection for Connecting Lines

The connecting lines should use double-sided electrolytic copper material with 18/12.5 specifications(except in special cases). Their main function is to achieve connections between electronic devices, and there is no special requirements for the degree of bending. They only needs to be welded and fixed at both ends, but it must be ensured that there are no abnormalities after being bent back and forth more than 8 times before it can be put into use.

3. Material Selection for Sliding Covers

The material recommended for the double-layer sliding cover is single-sided adhesive-free electrolytic copper with 1/3OZ specifications, which has good flexibility and ductility. For double-sided sliding cover boards, it is also recommended to use double-sided adhesive-free electrolytic copper with 1/3OZ specifications.

It is worth noting that the service life of the sliding cover board made of double-sided adhesive-free electrolytic copper with 1/3OZ specifications have a longer lifespan compared to the double-layer board made of single-sided adhesive-free electrolytic copper with 1/3OZ specifications. Under the condition of reasonable structural design, it is recommended to design the FPC as a double-sided sliding cover as much as possible.

In terms of cost, using double-sided adhesive-free electrolytic copper with 1/3OZ specifications increases costs by about 30% compared to using single-sided adhesive-free electrolytic copper with 1/3OZ specifications. However, the production yield and test life will also be improved accordingly, thereby ensuring the stability of use of such boards.

4. Material Selection of Multilayer Flexible PCBs

For multilayer flexible PCB material selection, it is recommended to use adhesive-free electrolytic copper with 1/3OZ specifications. This material has good softness and ductility, which can ensure that the manufactured flip boards can pass the corresponding tests when there are no obvious structural problems.

5. Selection of Auxiliary Materials

When selecting adhesive tape materials, if ordinary boards do not require SMT (such as side key boards), you can choose adhesive tape that is not resistant to high temperatures. However, if SMT is required (such as button boards), high temperature resistant adhesive tape must be used.

6. Selection of Conductive Materials

When choosing conductive adhesive tape, ordinary conductive adhesive is suitable for situations where conductivity requirements are not high, such as ordinary button boards. For applications with higher conductivity requirements that must use adhesive tape materials, such as special button boards, it is recommended to use adhesive tape with better conductivity. However, in general, we do not recommend using this type of adhesive tape because of its relatively high price.

Conductive fabric has excellent conductivity but does not perform very well in terms of adhesion, and is generally suitable for button board applications.

Conductive pure adhesive is a material with high -strength conductive properties, commonly used for bonding steel sheets. However, we do not recommend users to use this conductive pure adhesive because the price is relatively high.

HoYoGo is an international, professional and reliable FPC factory, we are committed to providing customers with stable quality, professional FPC manufacturing and FPC assembly services. We have 13 years of experience in FPC production. If you have relevant needs, you are welcome send us your inquiries.

评论

发表评论