Future Development of PCB and FPC

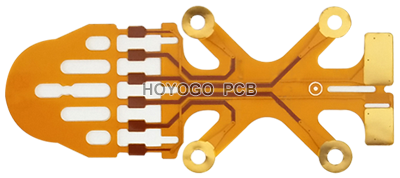

Future Development of FPC

Based on the vast market of China's FPC, large companies in Japan, the United States, and other countries and regions have already set up factories in China. By 2012, both flexible circuit boards and rigid circuit boards have achieved great development. However, if a new product follows the “start-development-climax-decline-elimination” rule, FPC is now in the area between the climax and decline. Before no product can replace the flexible board, if the flexible board continues to occupy market share, it must be innovated. Only innovation can make it out of this strange circle.

So, what aspects will FPC continue to innovate in the future? There are four main aspects:

1. Thickness. FPC thickness must be more flexible and thinner;

2. Folding resistance. Flexibility is an inherent function of FPC. Future FPCs must be more resistant to folding and must exceed 10,000 times.

3. Price. At this stage, the price of FPC is much higher than PCB. If the price of FPC falls, the market will definitely become wider.

4. Technological Level. In order to meet various requirements, the FPC process must be upgraded and the minimum aperture and minimum line width / space must meet higher requirements.

Therefore, FPC's innovation, development and upgrade in these four aspects can usher in the second spring!

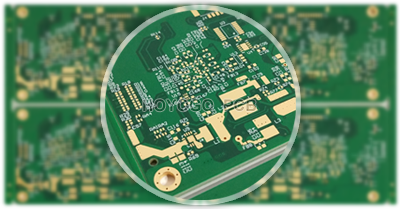

Future Development of PCB

Printed circuit boards have evolved from single-layer to double-sided, multi-layer and flexible, and still maintain their respective development trends. As the PCB industry continues to develop in the direction of high precision, high density, and high reliability, and continues to shrink volume, reduce costs, and improve performance, printed circuit boards will still maintain a strong vitality in the future development of electronic equipment.

In summary, the development trend of future circuit board manufacturing technology is basically the same at home and abroad, that is to develop in the following directions: high density, high precision, fine aperture, fine wire, fine pitch, high reliability, multi-layer, high-speed transmission, light weight, thin, etc. And in terms of production, it is developing to improve productivity, reduce costs, reduce pollution, and adapt to the production of multiple varieties and small batches. The level of technological development of printed circuit boards generally depends on the line width, aperture, and board thickness / aperture ratio of the printed circuit board.

Summary:

In recent years, the consumer electronics market, head by mobile electronic devices such as smart phones and tablet computers, has grown rapidly, and the trend toward smaller and thinner devices has become increasingly apparent. As a result, traditional PCBs have been unable to meet product requirements. Therefore, major manufacturers have begun to study new technologies to replace PCBs, and FPC, as one of the most popular technology, is becoming the main connection fittings for electronic equipment.

In addition, the rapid rise of emerging consumer electronics markets such as wearable smart devices and drones has also brought new growth space for FPC products. At the same time, the trend of display and touch of various electronic products also makes FPC enter a wider application space of small and medium-sized LCD screens and touch screens, and the market demand is increasing.

评论

发表评论