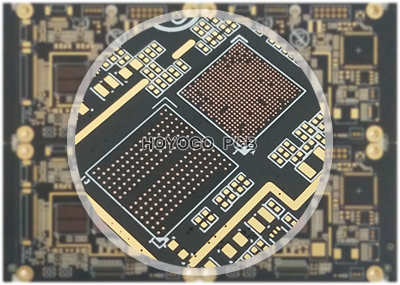

High Precision HDI PCB

The heat resistance of HDI board is an important item. The thickness of HDI boards is getting thinner and thinner, and the requirements for heat resistance are getting higher and higher. The advancement of lead-free process has also increased the requirements for the heat resistance of HDI boards, and because HDI boards are different from ordinary multilayer through-hole PCB circuit boards in terms of layer structure, the heat resistance properties of the two is different.

The heat resistance defects of HDI board are mainly break and delamination. So far, based on the heat resistance test experience of various materials and HDI boards, it is found that the areas with the highest probability of HDI board break are the areas above the dense buried holes and the areas below the large copper surface.

Heat resistance refers to the ability of the PCB to resist the thermo-mechanical stress generated during the soldering process. The delamination mechanisms of PCB in heat resistance test generally include the following:

1. When the temperature changes, different materials inside the test sample have different expansion and contraction characteristics, and internal thermo-mechanical stress is generated inside the sample, which will cause cracks and delamination.

2. The small defects (including cavities, microcracks, etc.) inside the test sample are places where the thermo-mechanical stress is concentrated, and are the function of the axial stress amplifier. Under the action of the internal stress of the sample, it is easier to cause cracks or delamination.

3. Volatile substances in the test sample include organic volatile components and water. When high temperature and drastic temperature changes, rapid expansion will generate huge internal vapor pressure. When the expanded steam pressure reaches the small defects(including voids, microcracks, etc.) inside the test sample, the amplification corresponding to the small defects will cause segmentation.

The HDI board is prone to delamination above the dense buried holes, which is caused by the special structure of the HDI board in the buried hole distribution area. Stress analysis in the area with or without buried holes. In the heat resistance test, when the area without buried holes undergoes thermal expansion, the expansion in the Z direction at each position on the same plane is uniform, so there is no stress concentration area caused by structural differences. When a buried via is designed in the area and the buried via is drilled on the surface of the substrate, on the A-A section between the buried via and the buried via, the substrate will not be restricted by the buried hole in the Z direction, so the expansion amount is relatively large. On the B-B section where the buried via and the pad are located, since the substrate is constrained by the buried via in the Z direction, the expansion amount is small. The difference in the expansion of these three places causes stress concentration at the junction of the buried hole and the HDI medium and plugging resin and nearby areas, which makes it easier to form cracks and delamination.

The HDI board is prone to stratification below the large outer copper surface. This is because the PCB will heat up during installation and welding, and volatile substances (including volatile organic compounds and water) will expand rapidly. The large copper outer surface prevents timely escape of volatile substances. So, a huge internal steam pressure is generated. When the expanded steam pressure reaches the small defects inside the test sample, including voids, micro cracks, etc., the amplifier action corresponding to the small defects will cause delamination.

HOYOGO is an international, professional and reliable PCB Manufacturer. Our production is producing rigid PCB from 2~56layer with small- medium- mass volume. In the meantime, we can offer you FPC, Rigid-flex, HDI, all other special PCBs from our partner production.

评论

发表评论