PCB Changes after SMT

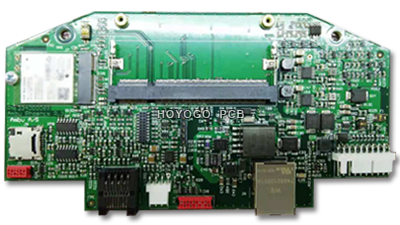

After PCB soldering the component, it is called PCBA.

PCB has no function, it can only function with the circuit after smt. PCB raw material: copper clad laminate is the base material for manufacturing printed circuit boards. In addition to supporting various components, electrical connection or electrical insulation between them can also be achieved. In short, it is a thin board containing integrated circuits and other electronic components. It will appear in almost every electronic device. If there are electronic components in a certain device, they are all mounted on PCBs of different sizes. In addition to fixing various small parts, the main function of the PCB is to provide electrical connections between the upper parts.

What is SMT?

SMT is an abbreviation for surface mount technology. SMT is a new generation of electronic assembly technology, and it is also the most popular technology and process in the current electronic assembly industry. It compresses traditional electronic components into devices that are only a few tenths of the volume.

SMT History

Surface mounting is not a new concept, it is derived from earlier processes, such as flat panel mounting and mixed mounting. In the assembly of electronic circuits, a point-to-point wiring method was initially adopted, and there was no substrate at all. The packaging of the first semiconductor device used radial pins, which were inserted into the through holes of the monolithic circuit boards used for resistor and capacitor packaging. In the 1950s, flat surface mount components were used in the highly reliable military field. In the 1960s, hybrid technology was widely used. In the 1970s, passive components were widely used under the influence of Japanese consumer electronics products, and active components were widely used in the past decade.

SMT Advantages

The assembly density is high, and the electronic products are small in size and light in weight. The volume and weight of the patch component is only about 1/10 of the traditional plug-in component. After SMT is generally adopted, the volume of electronic products is reduced by 40% to 60%, and the weight is reduced by 60% to 80%.

SMT products have high reliability and strong vibration resistance; although the defect rate of the solder joints is low, but the high frequency characteristics are good; and it reduces electromagnetic and radio frequency interference. It is not only easy to realize automation, but also improves production efficiency and reduces costs by 30%~50%. It also saves materials, energy, equipment, manpower, time, etc.

评论

发表评论