The Importance of PCBA Processing First Article Inspection

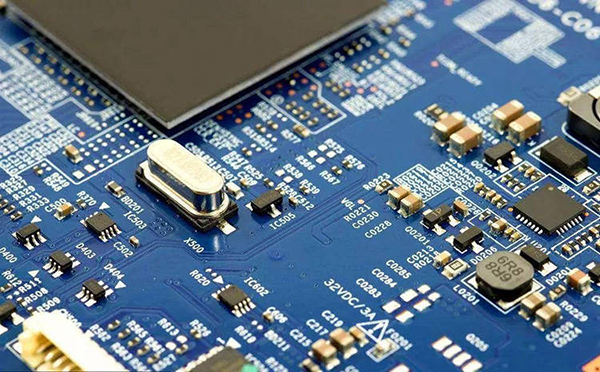

The first article PCBA processing inspection means that the PCBA inspects the first produced PCBA product in each processing link. The first article inspection is an important control point to inspect the processing quality of the product. The first article must meet the document requirements before mass production.

First article inspection can detect problems as early as possible and prevent batch errors during PCBA processing. Through the first article inspection, it can be found whether there are errors such as mispaste, missing paste or multiple paste on the PCBA board, and corrective or improvement measures can be taken in time.

At present, many PCBA processing factories use the first article detector to judge the first article, only need to input the product's BOM, coordinates, bit number map, and then the system will automatically check the first article of product. It can check whether the data in the BOM is consistent with processing, can also reduce the error in manual inspection, save labor costs, improve efficiency, and provide customers with high-quality products. It is an essential process for PCBA processing plants to ensure product quality and improve production efficiency.

The first article inspection generally occurs when the new product is launched for the first time, shift change, line change, the equipment parameter adjustment, and the PCBA of the same type is different. When the quality problem of the first article is found, it should be reported and dealt with in a timely manner, and the unqualified projects should be re-confirmed.

HoYoGo is an international, professional and reliable PCB manufacturer, including one-stop service from upstream electronic components procurement to PCB production and processing, SMT placement, PCBA testing, finished product assembly, etc. If you have related PCB requirements, please contact us.

评论

发表评论