How to Judge the Quality of the Blind & Buried Vias in PCB

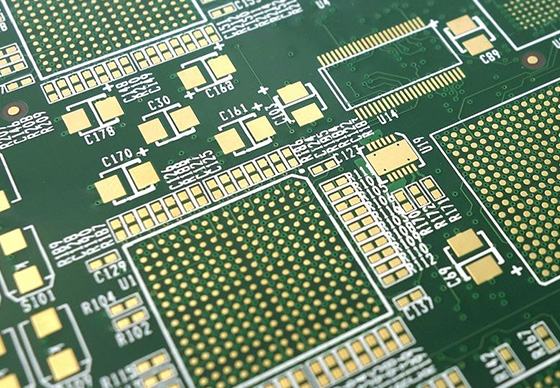

Blind & buried PCB is a high density, high precision printed circuit board. Its special structure and complex technology are widely used in high-end electronic products. If you buy poor quality products, there will be various problems need to be dealt with. So in order to avoid this situation, how should we judge the quality of blind & buried vias in PCB?

1. Check the diameter, depth and wall thickness of blind vias

These aspects of qualified blind & buried vias all meet the standard requirements, while unqualified ones may have quality problems in these aspects. Such as the hole diameter is too large, the hole depth is not enough, the hole wall is too thin and so on.

2. Check the piercing quality of blind vias

Qualified blind & buried vias should have no burr, no broken edges, and no crack when piercing, while unqualified ones may have these quality problems. These problems may lead to failure of buried blind s in use.

3. Check the plating quality of blind vias

Qualified blind & buried PCB should be uniform, smooth, and not easy to peel off during plating, while the unqualified ones may have problems such as uneven plating, insufficient plating thickness, and plating peeling. These problems may also lead to failure of blind and buried via during use.

As mentioned above, the quality of blind & buried PCB is closely related to the blind diameter, hole depth and hole wall thickness, perforation quality, and plating quality, etc.

HoYoGo is an international, professional and reliable PCB manufacturer, we have an excellent and stable quality system to support various complex processes. The blind & buried via PCB we produce strictly meets the requirements of the blind & buried via technology, and has been well received by customers.

评论

发表评论