What are the Advantages and Disadvantages of Hybrid PCB

In the PCB manufacturing technology, boards made of different base materials are mixed and pressed together, which is called hybrid PCB. So what are its advantages and disadvantages?

Advantages:

1. High Reliability

Hybrid PCB is a circuit board and different substrates that are pressed together through a hot pressing technology, which can effectively improve the mechanical strength and electrical connection performance of the entire circuit board, thus improving the reliability and stability of the product.

2. High signal transmission efficiency

The hybrid PCB can realize high-speed and high-frequency signal transmission through multi-layer design, and can also reduce signal interference and distortion, and improve signal transmission efficiency and quality.

3. Good cooling performance

Hybrid PCB can closely combine the circuit board and the substrate to form an integral heat conductor, thereby effectively improving the heat dissipation performance of the entire circuit board and reducing the impact of temperature changes on electronic components.

4. High design flexibility

Hybrid PCB can realize complex circuit functions through multi-layer design, and can also be customized according to the actual needs of the product, with high design flexibility and adaptability.

Disadvantages:

1. High manufacturing cost

Hybrid PCB needs to be made through multiple processes, and the manufacturing cost is higher than that of ordinary PCB.

2. Difficult technology

The manufacturing technology of the hybrid PCB board is relatively complicated, requiring high-precision equipment and technical personnel for operation and maintenance.

3. High environmental requirements

The manufacturing technology of hybrid PCB needs to use high temperature and high pressure conditions, which has high requirements on the environment and is easily affected by external factors.

Because the hybrid PCB technology has certain requirements on the PCB manufacturer's process capabilities, it is necessary to find a professional manufacturer to manufacture it to avoid quality problems.

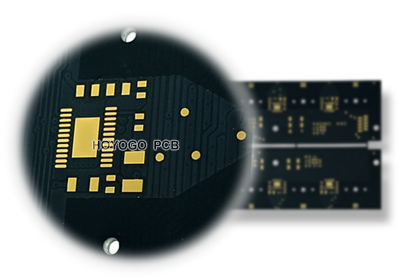

HoYoGo is an international, professional, top 15 PCB manufacturer in China, we are able to meet customers' requirements for hybrid PCB technology. At the same time, HoYoGo also has an excellent and stable quality system, which supports various complex technology, such as custom lamination structures, super thin boards, large-size boards, etc.

评论

发表评论