The Application of Aluminum PCB in Automotive Lighting

The use of aluminum PCB in automotive lighting systems can be said to "put on" a high-tech "cooling jacket" for the car. This not only allows the car's lights to shine farther and brighter, but also ensures that the lights will not be interrupted due to overheating after a large-scale rock concert-level performance.

1) High Thermal Conductivity

If we compare LED lights to superheroes, then the aluminum PCB can be regarded as an important supporter behind them, specifically responsible for solving heat dissipation problems. The excellent thermal conductivity of the aluminum substrate is like an efficient air conditioning system, which can keep it "cool".

2) Mechanical Stability

Aluminum PCB acts like an indestructible shield, maintaining its shape and functionality even in harsh environments. When the car travels through the desert or snow, the aluminum substrate can ensure that the lighting system is as stable as a mountain.

Application of Aluminum PCB in Automotive Lighting:

1) Headlight

The aluminum PCB in the headlight acts like a personal trainer, ensuring that the LED light does not overheat when working at high intensity. It constantly guides LED lights on how to effectively dissipate heat and maintain optimal performance.

2) Tail Lights and Interior Lighting

Although the taillights do not work as hard as the headlights, the LED lights are prone to overheating under long-term operation. The aluminum PCB acts as a cooler here, helping the LED lights to keep running at low temperatures and ensuring stable lighting.

3) Daytime Running Lights (DRL)

For daytime running lights, the aluminum PCB is like a big sunshade. Even under strong sunlight, LED lights can be effectively protected from damage, thereby extending their service life.

4) Signal Lights and Other Indicators

Although the signal lights do not work under high pressure, the aluminum PCB still provides continuous cooling support to ensure that they can quickly and accurately transmit information in emergency situations.

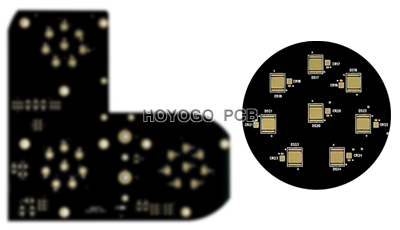

HoYoGo is an international, professional and reliable PCB manufacturer. We have our own factory, advanced machinery and an excellent and stable quality system, as well as high level automated and dedicated automotive production lines, automotive PCB accounting for 45% of our sales. We can also provide you with preferential prices for metal materials, support various complex processes, and customize all your needs. If you have relevant needs, please feel free to contact us!

评论

发表评论