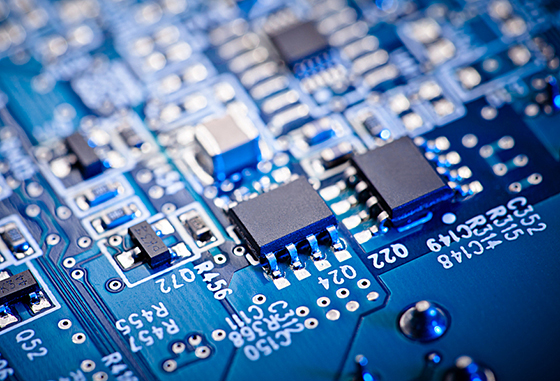

What are the Advantages of New Energy Vehicle PCB

As environmental protection and energy efficiency become increasingly important, the market demand for new energy vehicle PCB is growing rapidly. As the “intelligent heart” of new energy vehicles, PCB are responsible for managing and controlling the power system to ensure high-speed and stable driving for the vehicle. In order to ensure that your beloved new energy vehicle will not “strike” on the road, these PCB need to undergo rigorous testing and precision manufacturing to meet ultra-high standards, continuously improving performance and reducing energy consumption. So, what are the magical features of new energy vehicle PCB?

1. High Efficient Management

The electric drive system of new energy vehicles requires complex circuits to manage the flow and conversion of energy. New energy vehicle PCB is like an excellent commander. By optimizing energy flow, key components of electric vehicles such as electric motors and battery management system can operate in an optimal manner, thereby improving the efficiency of the entire vehicle. This management method helps to improve energy efficiency, extend cruising range, and minimize energy waste.

2. Lightweight Design

New energy vehicle PCB can designed into thin and light structures, which can reduce the overall weight of the vehicle compared with traditional vehicles and help improve the energy efficiency and driving mileage of new energy vehicles.

3. Strong Integration

New energy vehicle PCB can realize the integrated design of multiple functions, such as control system, battery management system, charging system, etc., making the entire automotive electronic system more compact and efficient.

4. High Reliability

Strict quality control and supervision ensure the reliability and safety of new energy vehicle PCB, reduce potential risks caused by electrical failures, and improve vehicle stability and reliability.

5. Energy Conservation and Environment Protection

New energy vehicle PCB is like an exquisite little energy saving expert, aiming to minimize energy waste and make the vehicle operation more environmentally friendly. Its design not only reduce dependence on traditional fuels, helping to reduce the burden on Mother Earth, but also uses environmentally friendly materials and technologies, which is more in line with the concept of energy conservation and environment than traditional fuel vehicle.

6. Sustainable Development

The design of new energy vehicle PCB is consistent with the concept of sustainable development and is conductive to promoting the development of the entire automotive industry in a more environmentally friendly and efficient direction.

7. Precision Control

The precision control of new energy vehicle PCB is like a equipping the car with a sophisticated “brain”. It can accurately control the speed of the motor, the charging and discharging process of the battery, and energy distribution, which can improve the power, energy efficiency and stability of the vehicle, thereby ensuring that the driving performance and safety of the vehicle are optimized under various complex conditions.

8. Intelligent Features

Some new energy vehicle PCB have unique intelligent characteristics. They can interconnect with other systems in the vehicle to realize advanced functions such as autonomous driving and remote monitoring, adding wisdom and convenience to the car.

HoYoGo is an international, professional and reliable automotive PCB factory, we can provide PCB manufacturing and one stop service from upstream electronic component procurement to PCB production processing, SMT patching, PCBA testing, finished product assembly, etc. All our products strictly follow the acceptance standards of IPC-A-600-H and IPC-6012, and we do not relax any step of inspection. If you have relevant needs, you are welcome to contact us!

评论

发表评论