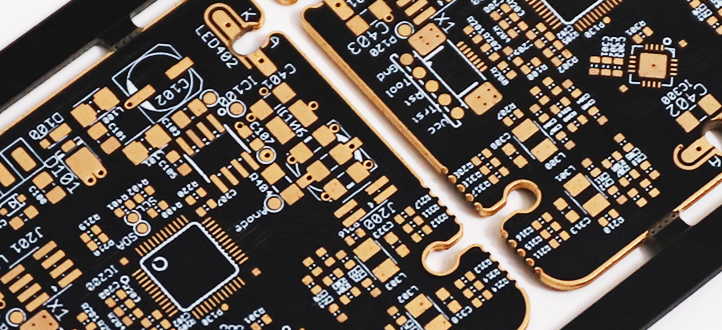

Key Requirements of Server and Data Storage PCB

Servers and data storage place stringent demands on PCBs to ensure high performance, reliability, and efficiency. These demands stem from the need to process large amounts of data, achieve high-speed communications, and provide uninterrupted services. Here are some key requirements for PCBs in the server and data storage space:

1. High Data Rates and High Bandwidth

With the increasing demand for data-intensive applications and high-speed communication protocols, PCB must be capable of supporting high data rates and high bandwidth. To achieve this goal, technologies such as controlled impedance, carefully designed routing, and advanced materials are used to minimize energy loss in the signal and ensure data integrity.

2. Thermal Management

Servers and data storage systems generate a lot of heat during operation, which, if not managed properly, can lead to performance degradation or component failure. Therefore, PCBs must employ thermal management solutions such as thermal vias, heat sinks, and specialized thermal interface materials to ensure effective heat dissipation.

3. Power Integrity

Proper power distribution and management are crucial for server and data storage PCB. Such circuit boards must ensure stable power supply to various components to minimize noise and ensure reliable operation. This is achieved through power distribution networks, decoupling capacitors, and advanced power integrity design techniques.

4. Signal Integrity

High-speed signals and dense component integration can cause signal integrity issues such as crosstalk, reflections, and electromagnetic interference(EMI). Hence, PCB for servers and data storage need to be designed with signal integrity in mind, using techniques such as controlled impedance, ground planes, and shielding to maintain signal quality.

5. Electromagnetic Compatibility (EMC)

Servers and data storage systems must comply with EMC regulations to prevent interference with other electronic equipment and ensure safe operation. PCBs play a critical role in EMC compliance by incorporating shielding, grounding, and filtering techniques to minimize electromagnetic emissions and enhance immunity to external interference.

6. High Reliability and Long Service Life

Server and data storage PCBs need to operate continuously and reliably for long periods of time, often in harsh environments. These PCBs must be carefully designed and manufactured to withstand harsh conditions such as extreme temperatures, vibration, and humidity.

By meeting these stringent requirements, PCBs can support the high-performance, data-intensive, and mission-critical nature of servers and data storage systems, and can also process and store data securely and efficiently.

HoYoGo is an international, professional and reliable PCB manufacturer. We have a strong quality management system and have obtained ISO 9001 certification to ensure stable product quality and reliable performance. We can provide high-quality PCB manufacturing and assembly services for servers and data storage. If you have related PCB needs, please feel free to send us inquiries.

评论

发表评论