LED PCB: The Key to Automotive Lighting

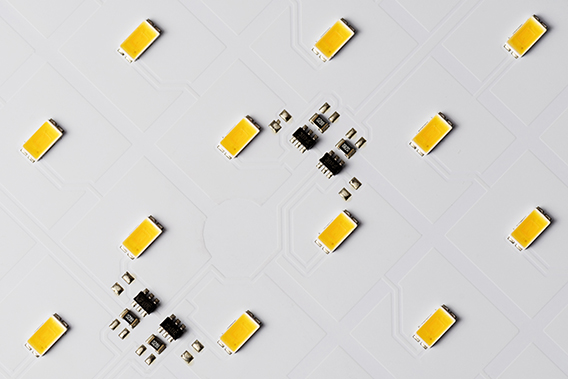

In the field of automotive electronics, LED PCBs have become core components for improving lighting performance and driving safety. With their lightweight, bright, and durable features, LED PCBs significantly improve the night driving experience, ensuring the safety and convenience of night driving.

Why Choose LED PCB

The battery life, energy efficiency and long service life of LED lights have been widely recognized. However, the role of the LED PCBs are not just to house these lights, they also ensures the optimal operation of the LED lights through: efficient heat dissipation management, voltage regulation, and reliable connections to ensure the stability and durability of the LED lights.

Key Advantages of LED PCB in Automotive Applications

1. Lightweight Design

LED PCBs are made from lightweight, high-performance materials, which can significantly reduce the weight of vehicle lighting components compared to traditional lighting systems, thereby improving fuel efficiency and overall vehicle performance.

2. Enhanced Brightness

Precisely designed LED PCBs maximize the light output of LEDs, ensuring wide-angle, high-brightness illumination during night driving. This not only improves driving convenience, but also greatly improves driving safety by providing clear road visibility.

3. Superior Durability

Automobiles present numerous challenges for electronic components, such as vibration, temperature fluctuations and humidity. Our LED PCB uses high temperature and vibration resistant materials to ensure stable performance and extended service life in these harsh environments.

Practical Applications of LED PCBs in Vehicles

LED PCBs are commonly used in:

· Headlights

· Taillights

· Interior lighting systems

· Dashboard backlighting

· Custom ambient lighting

In particular, custom ambient lighting is becoming increasingly popular in high-end vehicles, serving as an important element to enhance the user experience.

HoYoGo is an international, professional and reliable automotive LED PCB manufacturer. We have our own factory, advanced machines and excellent and stable quality system, as well as highly automated and dedicated automotive PCB production lines. Automotive PCBs account for 49% of our sales. If you have related needs, please feel free to contact us!

评论

发表评论