Why Use Ceramic PCB for Micro-Pressure Sensors

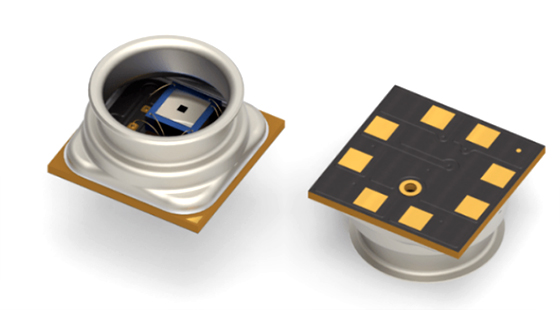

The primary reason for using ceramic PCBs in micro-pressure sensors is that ceramic materials possess excellent mechanical, electrical, and thermal properties, making them particularly suitable for sensors operating in high-precision and harsh environments. Specifically, the use of ceramic PCB in micro-pressure sensors shows many advantages:

1. High Thermal Stability

Ceramic materials have a low coefficient of thermal expansion, which enables them to maintain good dimensional stability in extreme temperature environments. This is critical for micro-pressure sensors, which need to measure minute pressure changes accurately. Any thermal expansion or contraction could negatively impact measurement accuracy. Ceramic PCBs can maintain stable performance in both high and low temperatures, ensuring the reliability and precision of micro-pressure sensors.

2. High Mechanical Strength

Micro-pressure sensors are often used in fields where pressure sensitivity and harsh environments are involved. Ceramic materials have extremely high mechanical strength and impact resistance, enabling them to withstand external vibrations and mechanical stress, ensuring the long-term stability of the micro-pressure sensor. Compared to traditional FR-4 or other organic substrates, ceramic materials are less prone to deformation or damage.

3. Excellent Electrical Insulation

Ceramic materials have excellent electrical insulation properties, which can effectively reduce electrical interference and ensure the stability of the micro-pressure sensors signal. This characteristic is crucial, as micro-pressure sensors must accurately handle minute electrical signals, any noise or interference may lead to measurement errors.

4. Strong Corrosion Resistance

When micro-pressure sensors operate in a harsh environment, they may come into contact with corrosive gases or liquids. Ceramic materials have excellent corrosion resistance and can withstand long-term erosion to acids, alkalis and other chemicals, thus helping to extend the service life of the micro-pressure sensor. This makes them well-suited for applications in industries such as chemical processing, medical, environmental monitoring, and more.

5. Good Thermal Conductivity

Ceramic PCB has high thermal conductivity, allowing them to dissipate heat rapidly and prevent the micro-pressure sensor from overheating during operation. Especially in industrial applications, micro-pressure sensors may need to operate continuously for a long time. Good heat dissipation helps maintain the stable operation of the sensor, avoiding temperature fluctuations that could impact measurement results.

6. High-precision Circuit Integration

Ceramic PCBs are suitable for manufacturing highly precise and miniaturized sensor circuits. Their unique high stability and easy processing characteristics enable ceramic PCBs to integrate complex circuits and achieve compact sizes. This feature has great advantages for micro-pressure sensors with miniaturization and high precision requirements.

HoYoGo is an international, professional and reliable ceramic PCB manufacturer with many years of experience in ceramic PCB production. We an realize the production of high-tech, high-quality, and high-difficulty performance PCBs, can guarantee the quality and reliability of every product delivered to our customers. Additionally, we offer competitive pricing on ceramic materials. If you have a need for ceramic PCB production, please feel free to contact us!

评论

发表评论