Application of UV Sterilization Lamp PCB in Medical Equipment

UV sterilization technology is widely used in the medical field due to its high efficiency and chemical-free residue characteristics. As the core control component, the UV sterilization lamp PCB directly impacts the performance and safety of the equipment. So, what are the applications of UV sterilization lamp PCBs in medical devices?

1. UV Sterilization Equipment

Application Scenarios: Hospital wards, operating rooms, laboratories, etc.

Function: The UV lamp generates UVC light, which destroys the DNA/RNA of microorganisms, achieving sterilization.

Role of PCB: Controls the on/off switching of the lamp, adjusts UV intensity, sets timers, and ensures safe operation, such as automatic shutoff upon human detection. As a type of medical PCB, the UV sterilization lamp PCB plays a critical role in ensuring the efficient and safe operation of sterilization equipment.

2. Portable UV Sterilization Devices

Application Scenarios: Homes, clinics, ambulances, etc.

Function: Used for quick sterilization of small medical instruments, masks, phones, etc.

Role of PCB: Manages battery power, controls the UV lamp, provides charging management, and displays status. Medical PCBs in portable UV sterilization devices enable low-power designs, ensuring stability and reliability in mobile scenarios.

3. UV Water Sterilization Systems

Application Scenarios: Hospital water supply systems, laboratory pure water systems, etc.

Function: Uses UV light to sterilize bacteria, viruses, and other microorganisms in water.

Role of PCB: Controls the UV lamp, monitors water flow, adjusts UV intensity, and ensures sterilization effectiveness. The UV sterilization lamp PCB enables intelligent water flow detection and sterilization control, ensuring water safety.

4. UV Surface Sterilization Robots

Application Scenarios: Hospital wards, operating rooms, etc.

Function: Automatically moves and sterilizes surfaces using UV light.

Role of PCB: Controls robot movement, UV lamp operation, obstacle avoidance systems, and timed sterilization functions. Medical PCBs in robots enable precise motion control and obstacle avoidance, ensuring efficient and safe sterilization.

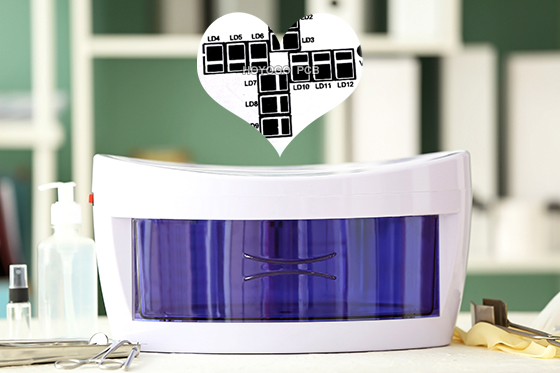

5. UV Sterilization Cabinets

Application Scenarios: Hospitals, clinics, laboratories, etc.

Function: Used for sterilizing medical instruments and laboratory tools.

Role of PCB: Controls the UV lamp, timer functions, and door lock safety systems to ensure safe sterilization. The UV sterilization lamp PCB in cabinets provides multiple safety protections, preventing UV leakage and ensuring user safety.

6. UV Sterilization Pens

Application Scenarios: Personal care, small medical instrument sterilization.

Function: Portable UV sterilization for small-scale items.

Role of PCB: Manages battery power, controls the UV lamp, provides charging management, and displays status. Medical PCBs in sterilization pens enable compact designs and efficient power management, meeting the needs of personal care scenarios.

Key Considerations for UV Sterilization Lamp PCBs

1. Safety

Human Detection: Uses infrared or microwave sensors to detect human presence and automatically shut off the UV lamp.

Door Lock Control: Sterilization cabinets require door lock control circuits to ensure the UV lamp only operates when the door is closed.

Emergency Stop: Includes an emergency stop button to immediately shut down the device in case of emergencies.

2. Reliability

Component Selection: High-reliability components ensure long-term stable operation of medical sterilization equipment.

Thermal Management: Proper heat dissipation design prevents high temperatures from affecting component lifespan.

Protection Design: Includes protective circuits to prevent overvoltage, overcurrent, and short circuits.

3. Intelligence

Timer Control: Uses MCUs or timer chips for precise timing control.

Intensity Adjustment: Adjusts UV intensity based on sterilization needs, extending lamp life.

Status Display: Uses LEDs or LCDs to display device status for user convenience.

4. Energy Efficiency

Low-Power Design: Optimizes circuit design to reduce standby power consumption.

Energy Recovery: Includes energy recovery circuits to improve energy utilization.

HoYoGo is an international, professional, and reliable PCB manufacturer. We specialize in producing UV sterilization lamp PCBs, providing high-quality solutions for the medical, laboratory, and public health industries. Our PCBs use high-temperature-resistant and UV-aging-resistant materials, featuring efficient heat dissipation, stable driving, and intelligent control to ensure long-term stable operation of UV-C lamps and achieve excellent sterilization effects. If you have related needs, please feel free to send us an inquiry!

评论

发表评论