Applications of Automotive PCBs in Active Noise Control(ANC) Systems

With the rapid development of vehicle electrification, intelligence, and comfort, in-cabin NVH (Noise, Vibration, and Harshness) performance has become a key indicator of overall vehicle quality. In particular, for new energy vehicles, the significant reduction of engine noise makes wind noise, road noise, and high-frequency tonal noise from electric drive systems more noticeable. As a result, traditional passive sound insulation methods are increasingly insufficient to meet the rising expectations for cabin comfort.

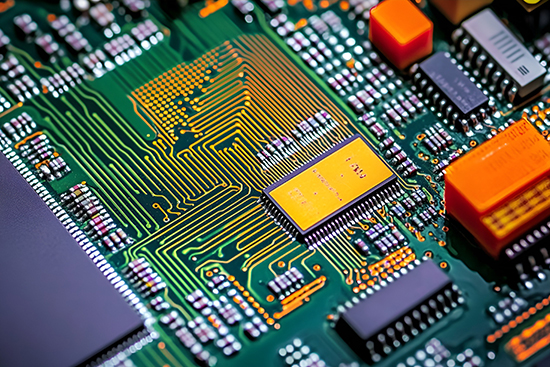

Against this backdrop, automotive Active Noise Control (ANC) systems have emerged as an effective solution. As a professional automotive PCB manufacturer, HoYoGo provides reliable PCB platforms for ANC mixed-signal chains and real-time algorithm processing, enabling low-noise performance, strong immunity to interference, and long-term reliable operation, helping vehicles maintain excellent NVH performance under complex operating conditions.

1. Operating Principle of Active Noise Control Systems

Automotive Active Noise Control (ANC) systems operate based on the principle of acoustic wave interference and are primarily used to suppress low-frequency, stable, or quasi-periodic noise inside the vehicle cabin. The system uses microphones positioned throughout the cabin to capture ambient noise in real time. The control unit then analyzes the acquired signals and, using adaptive filtering algorithms, generates an anti-phase compensation signal with matched amplitude. This signal is played through the vehicle’s loudspeakers, effectively reducing noise at the occupants’ listening positions.

Due to the complex and dynamically changing in-cabin acoustic environment, the noise cancellation process places extremely high demands on signal acquisition accuracy, system processing latency, and algorithm stability. Any errors in timing, phase, or amplitude can significantly degrade noise reduction performance. As a result, the electronic control unit of an ANC system imposes stringent requirements on the PCB, particularly in terms of low-noise analog front-end design, high-speed signal integrity, power and clock stability, and electromagnetic compatibility (EMC) performance.

2. The Core Role of Automotive PCBs in Active Noise Control Systems

1) Signal Acquisition and Front-End Processing

In an Active Noise Control (ANC) system, one or more microphones are used to capture noise signals from different locations within the vehicle cabin. These weak analog signals are first amplified and filtered by low-noise front-end circuitry before being forwarded to the downstream processing unit. The front-end stage is typically built around audio acquisition and processing ICs and integrated on automotive PCBs designed to meet stringent automotive-grade reliability requirements.

The layout and routing of the PCB have a direct impact on audio signal quality. By applying low-noise design practices, proper impedance control, and well-planned grounding, crosstalk and electromagnetic interference can be effectively reduced. This helps ensure that noise signals are captured accurately and completely, providing a reliable input foundation for subsequent adaptive algorithms.

2) Real-Time Digital Signal Processing (Low-Latency Closed-Loop Control)

The core of an Active Noise Control (ANC) system lies in real-time algorithm execution. The control unit typically employs DSP-capable MCUs, standalone DSPs, or integrated audio processors to perform low-latency processing of the acquired noise signals. This places stringent requirements on the PCB in terms of high-density routing, signal integrity, and effective isolation between analog and digital noise domains.

Multi-layer automotive PCBs, with a well-planned stack-up, enable effective planning and separation of power, signal, and ground layers. This helps reduce crosstalk and noise coupling, improving clock quality and overall system timing stability. In addition, good thermal design helps ensure the processor’s long-term reliable operation under high-load operating conditions.

3) Audio Output and Power Amplification

After the anti-phase compensation signal is calculated, the system drives the loudspeakers through a power amplifier to generate the acoustic output. Power amplification circuits typically carry relatively high currents, especially peak currents, placing stringent requirements on PCB copper thickness, trace width, via current-carrying capability, and thermal management design.

High-reliability automotive PCBs can reduce power losses and heat generation while maintaining sufficient safety margins through low-impedance power distribution and well-designed thermal spreading structures. This ensures stable and reliable operation of the Active Noise Control system during prolonged operating periods.

3. Key Performance Requirements for Automotive PCBs in Active Noise Control Systems

1) High Reliability and Environmental Robustness

The automotive environment is highly demanding, with electronic systems subjected to continuous temperature cycling as well as mechanical vibration and shock. Active Noise Control (ANC) systems are typically required to operate reliably within automotive-grade temperature ranges, such as -40℃ to 125℃, depending on installation location and vehicle requirements, while maintaining stable performance throughout the vehicle’s entire lifecycle. Therefore, automotive PCBs must offer strong thermal resistance, moisture resistance, and vibration durability, and long-term reliability can be improved through material selection and process control to ensure stable system operation under complex operating conditions.

2) Excellent EMC Performance

Active Noise Control (ANC) systems represent a typical mixed-signal application in which analog audio signals coexist with digital processing and high-speed communication interface signals, placing stringent demands on electromagnetic compatibility (EMC) performance. Automotive PCBs must employ well-designed stack-up configurations, grounding strategies, and PCB-level isolation and shielding techniques to minimize electromagnetic interference and coupling risks, thereby preventing adverse effects on in-vehicle audio systems, communication modules, and other electronic subsystems.

3) Support for Miniaturization and System Integration

As vehicle electronic architectures continue to evolve toward higher levels of centralization, Active Noise Control (ANC) units are increasingly required to be tightly integrated with audio systems or cockpit domain controllers. This trend demands that PCBs achieve higher routing density and greater functional integration within limited space, while still maintaining good signal integrity and reliable performance under high-density design conditions.

HoYoGo is an international, professional and reliable automotive PCB manufacturer with high-level automated and dedicated automotive PCB production lines. Automotive PCBs account for 49% of our total output. Our manufacturing processes strictly follow high-quality management systems and are certified to ISO9001, ISO14001, ISO13485, and IATF16949. All products comply rigorously with the IPC-A-600-H and IPC-6012 acceptance standards. If you have any related PCB requirements, we welcome your inquiries.

评论

发表评论