Advantages of Using Multilayer Circuit Boards

Generally, the requirements for structure design and technology manufacturing of multi-layer electric boards are very high. The more layers, the more difficult it is, and it is suitable for more complex circuits. So what are the advantages of using multilayer circuit boards.

The advantages of using multilayer boards are:

1. High assembly density and small size;

2. Shorten the connection between electronic components and increase the signal transmission speed;

3. Convenient routing;

4. For high-frequency circuits, add a ground layer to make the signal line form a constant low impedance to the ground;

5. Good shielding effect.

However, the more layers, the higher the cost, the longer the processing cycle, and the more troublesome the quality inspection is.

Our common computer boards usually use 4-layer boards or 6-layer boards, but now there are more than 100 layers of practical printed circuit boards. The difference between the 6-layer board and the 4-layer board is in the middle, that is, there are two more internal signal layers between the ground layer and the power layer, which are thicker than the 4-layer board.

Multilayer boards are actually formed by laminating and bonding several etched single-sided or double-sided boards. The double-sided board is easy to distinguish. Look at the board with light, except for the routing on both sides, other places are transparent. For the 4-layer board and the 6-layer board, because the layers on the circuit board are very tightly integrated, if there are corresponding marks on the board, there is no good way to distinguish them.

For simple circuits such as radios, single-sided or double-sided manufacturing is sufficient. However, with the development of microelectronics technology, the complexity of circuits has greatly increased, and higher requirements have been placed on the electrical performance of circuit boards. If you still use single-sided or double-sided boards, the circuit volume will be very large, which will bring great difficulties to the routing. In addition, electromagnetic interference between the lines is not easy to handle, so multilayer boards have appeared. The number of layers means that there are several independent routing layers, usually an even number.

Circuit board manufacturers have 3 or more layers of conductor patterns for multilayer circuit boards, and the conductor layers are divided into inner and outer layers. The inner layer is a conductor pattern completely sandwiched inside the multilayer board; the outer layer is the conductor pattern on the surface of the multilayer board. Generally, the inner conductor pattern is processed first in the production process, and the hole and outer conductor pattern are processed after pressing, and the inner and outer layers are connected by metalized holes.

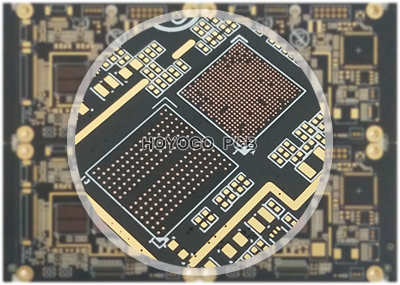

SHENZHEN HOYOGO ELECTRONIC TECHNOLOGY CO., LTD. is a PCB manufacturer with a mass production of 500,000 sqm factory and a medium-size production for small-medium volume. Our production is producing rigid PCB from 2~56layer with small- medium- mass volume. In the meantime, we can offer you FPC, Rigid-flex, HDI, all other special PCBs from our partner production.

评论

发表评论