What Should be Paid attention to When Cleaning PCBA

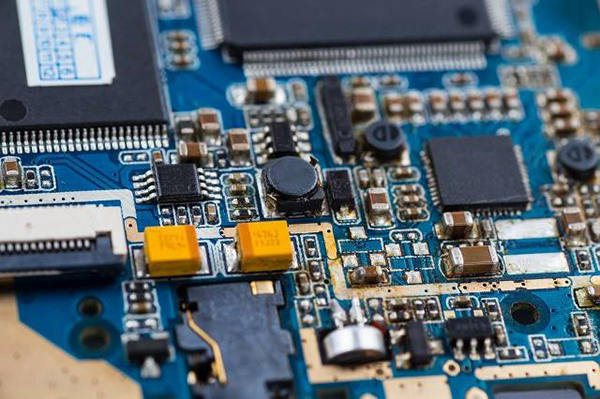

After the PCBA is processed and welded, some flux residues will remain on the surface. If the surface cleanliness cannot be effectively guaranteed, it may affect the use time of the PCBA, so effectively cleaning the circuit board in manufacturing process is a very important step. So what should we be pay attention to when cleaning the PCBA board?

1. After the PCBA board is soldered, the flux residue will corrode over time, so it should be cleaned in time after soldering.

2. When cleaning the PCBA, we must wear an electrostatic wristband and a protective mask.

3. When cleaning the PCBA, its necessary to protect the components and logos on the board to prevent the cleaning agent from entering the unsealed components, so as not to cause damage to the components.

4. Some electronic components are prohibited from contacting special cleaning agents, such as: key switches, buzzers, batteries, plastic components, etc.

5. During the cleaning process, metal such as tweezers cannot be used to directly touch the PCBA, so as not to damage or scratch the PCBA surface.

6. After the PCBA board is cleaned, it should be placed in an oven and baked. After drying, take out the PCBA board for the next process.

7. After cleaning, there should be no residual soldering flux, tin beads and tin slag on the board surface; the surface and solder joints should not be whitish or gray; the board surface should not be sticky.

8. The cleaned PCBA board should be placed and marked separately from the uncleaned PCBA board; the cleaned PCBA board should not directly touch the surface with hands.

HoYoGo is an international, professional and reliable PCB manufacturer, including one-stop service from upstream electronic components procurement to PCB production and processing, SMT placement, PCBA testing, finished product assembly, etc. We have our own factory and advanced machines. If you have related PCB requirements, please contact us.

评论

发表评论