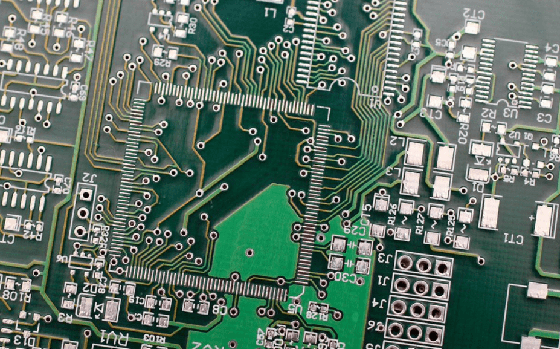

Why does PCB Pads Fall Off?

PCB pad falling off is a relatively common bad phenomenon in the PCBA processing process, that is, the phenomenon that the pads are separated from the PCB. As a necessary medium for welding and assembling electronic components and PCB boards, once the pads fall off, the PCBA products will fail to be used normally. So what are the reasons for the PCB pads to fall off?

PCB and soldering problems are the main cause of PCB pads falling off.

PCB problem: The poor adaptability of the copper foil and the resin of the PCB substrate will lead to the mismatch between the copper foil and the resin system, causing the PCB pad to fall off. In the PCB manufacturing process, excessive etching of the circuit leads to copper throwing or deformation of the pad due to the collision of the pad position during the processing process, which will also cause the PCB pad to fall off.

Welding problems: If the soldering process is too many times or the temperature is too high, it will cause the PCB pads to fall off. When the soldering iron is used to repair the board, the temperature of the soldering iron is too high and the soldering time is too long, which will also cause the PCB pads to fall off. When using the soldering iron, the operator exerts too much force, which will cause the pad to bear too much pressure on the iron head, which will also cause the PCB pad to fall off.

The above two points are the main reasons for the PCB pads to fall off. In addition to these two points, the PCB will also cause the PCB pads to fall off due to moisture. As we all know, because of the problem of board quality, PCB is absorbent. If the PCB gets wet during storage, it will cause the board to pop during soldering, and the popcorn board will also cause the pads to fall off.

HoYoGo is an international, professional and reliable PCB manufacturer. We have our own factory and related certificates, as well as experienced technicians and a number of QA staff. We strictly control every quality threshold, so that every customer can feel the best quality service.

评论

发表评论