What are the Method of PCB Panelization

PCB panelization: It is to splice several PCB together. It is not only improves production efficiency, saves costs, but also facilitates SMT welding in the later stage. So what are the methods of PCB panelization?

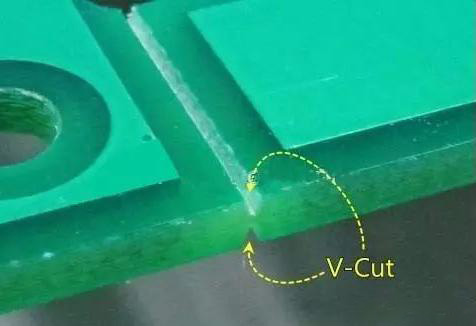

1. V-CUT

V-CUT is to put two or more PCB together, and then cut a V-shaped slot at the connection between the board and the board, which can be broken when in use. Since V-CUT can only cut straight lines, it is more suitable for rectangular PCB boards. Secondly, V-CUT also has certain requirements on the thickness of the PCB, generally requiring a thickness of more than 1mm. Because it is too thin, it will destroy the strength of the board itself, so the PCB with the thickness less than 1mm is not suitable for the V-CUT panelization method.

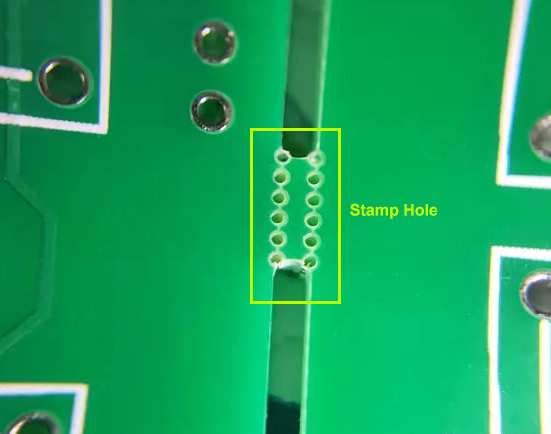

2. Stamp Hole

The stamp hole are some small holes drilled at the connection of the board to form a connection, and the burrs need to be removed all around. The size of the hole is generally about 0.3mm, and the distance between the hole and the hole is generally about 1mm, so it is easy to break and separate the board. Because the broken edge will show a jagged shape similar to the edge of a stamp, it is called a stamp hole. It is usually applied to PCB with irregular structures, such as "L" shaped structures.

To sum up, when we choose panelization method, the selection should be comprehensively considered according to the type of components and shape of the PCB, etc.

HoYoGo is an international, professional and reliable PCB manufacturer. Based on our rich experience and technology understanding, with own production capability, we are able to offer you one-stop service with small, medium to mass production with competitive terms, quality and delivery assurance that customized all your request.

评论

发表评论