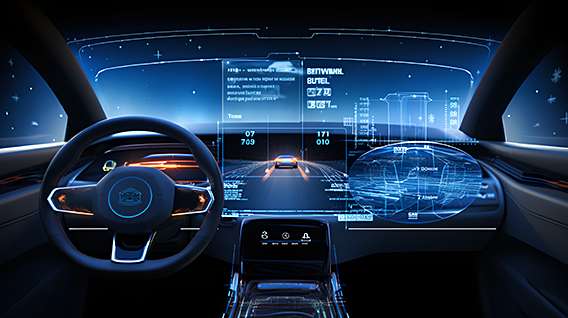

Application of GPS Navigation PCB in Automobiles

PCB is one of the key components in the automotive GPS navigation system. It is equipped with a GPS receiver module and other related electronic components, responsible for receiving and parsing GPS signals and providing location information. The following are the main functions and components of GPS navigation PCB in automobiles:

1. GPS Receiver Module

As the core component on the GPS navigation PCB, the GPS receiver module is mainly responsible for receiving signals from global positioning system satellites. These modules usually use a dedicated GPS receiver chip.

2. Signal Processing Circuit

The signal processing circuit in the GPS navigation PCB is used to amplify and filter the received GPS signal to ensure signal quality and stability.

3. Microcontroller (MCU)

The main function of the microcontroller (MCU) on the GPS navigation PCB is to process the data provided by the global positioning system (GPS) and execute the corresponding navigation algorithm. The MCU will achieve accurate positioning and path planning of objects based on the data collected by the GPS module.

4. Memory

The memory on the GPS navigation PCB is used to store GPS data, map data, navigation software, etc. The types of memory include Flash Memory and Random Access Memory (RAM), which ensure that the navigation system can quickly access and update data, thereby providing real-time navigation information.

5. Communication Interface

The communication interface in the GPS navigation PCB is used to realize data interaction between devices and provides a way for real-time data transmission. Common interfaces include USB interface, CAN bus interface, etc. These interfaces allow GPS data to be transmitted to external display screens or other systems, and support collaboration between multiple devices.

6. Auxiliary Circuit

The auxiliary circuits on the GPS navigation PCB mainly include clock circuits and reset circuits, etc. The function of these circuits is to ensure that the entire system can operate normally and continuously.

HoYoGo is an international, professional and reliable automotive PCB manufacturer. We provide PCB manufacturing and one-stop services from upstream electronic component procurement to PCB production and processing, SMT patch, PCBA testing, finished product assembly, etc. All our products strictly follow the acceptance standards of IPC-A-600-H and IPC-6012, and we will never relax any step of testing. If you have any related needs, please contact us!

评论

发表评论