Application of Rigid-flex PCB in Automobile

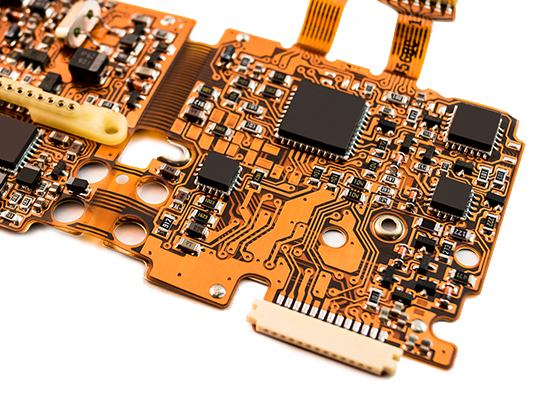

The application of rigid-flex PCB in automobiles is becoming more and more widespread. This type of PCB combines the advantages of rigid PCB and flexible PCB, providing higher design flexibility and performance advantages. So what are the applications of rigid-flex PCB in automobiles?

1. In-car entertainment system

The in-car entertainment system covers multiple functional modules such as navigation, audio, and information display. In order to meet these complex requirements, the complexity of wiring technology must be fully considered. The application of automotive rigid-flex PCB in these systems can effectively reduce space occupancy and wiring complexity, while improving system reliability and vibration resistance.

2. Advanced Driver Assistance Systems (ADAS)

ADAS includes automatic emergency braking, lane keeping assist and automatic parking. These systems have extremely high requirements for the accuracy and reliability of electronic equipment. Therefore, automotive rigid-flex PCB technology can realize the layout of complex circuits in a compact space to ensure the performance and stability of the system.

3. Dashboard and Display

Car dashboards usually integrate multiple displays and sensors, requiring complex circuit connections. The flexibility of the automotive rigid-flex PCB allows it to adapt to various shapes and sizes of instrument panels while ensuring the reliability of electrical connections.

4. Lighting system

The interior and exterior lighting system of automobiles, such as LED headlights, taillights, and interior ambient lights, can achieve more complex shapes and more compact layouts using rigid-flex PCBs while improving heat dissipation performance and reliability.

5. Sensor system

In order to monitor the vehicle condition and surrounding environment, the car is equipped with a variety of sensors, such as temperature sensors, pressure sensors, and camera systems. Automotive rigid-flex PCB can integrate with these sensors tightly together, reduce the number of connection points, and improving the reliability and response speed of the system.

6. Electronic Control Unit (ECU)

ECU is the core of the automotive electronic system, and its main responsibility is to control various electronic equipment and systems. Automotive rigid-flex PCB can meet the ECU’s requirements for high-density wiring, high reliability and high performance.

HoYoGo is an international, professional and reliable automotive rigid-flex PCB manufacturer. Our production strictly follows the high quality system and has passed ISO9001, ISO14001, ISO13485, TS16949 and C-UL-S certifications. All products strictly follow the acceptance standards of IPC-A-600-H and IPC-6012. The quality of our products has been widely recognized by customers in Europe and America. If you have any related needs, you are welcome to send us an inquiry.

评论

发表评论