How Automotive PCB Improve Driving Convenience and Comfort

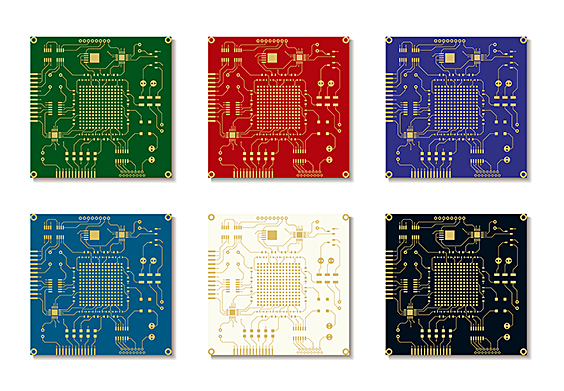

With the continuous development of automobile technology, driving experience and ride comfort have been significantly improved. In this process, PCBs play a crucial role. Automotive PCB are not only core components of the modern vehicle electronic systems, but also greatly enhance user comfort and convenience by supporting the functions of various body equipment.

1. Door Control and Seat Adjustment

As the core component of the car, the door control system includes door opening and closing, locking and power window lifting functions. The realization of these functions cannot be separated from the support of automotive PCB. Automotive PCB achieves automatic door opening and closing and smooth operation of power windows through precise control of sensors and motors.

Similarly, seat adjustment systems also rely on the efficient operation of automotive PCB. Whether it is the front and rear adjustment of the seat, the inclination adjustment of the backrest, or the realization of the seat heating and ventilation functions, automotive PCB plays a key role. The integration of these functions not only improves the comfort of the driver and passengers, but also further enhances the luxury of the vehicle.

2. Lighting System and Wiper Control

The vehicle’s lighting system includes not only the headlights and taillights, but also the dashboard, interior ambient lights, etc. Automotive PCBs ensure that the brightness and color of various light sources meet driving requirements through precise control of the lighting system, thereby improving driving safety and comfort. In particular, the interior ambient lighting creates a comfortable and pleasant interior environment for passengers through the adjustment of multiple colors and brightness.

The wiper control system also relies on the functionality implementation of the automotive PCB. The automotive PCB can accurately control the wiper motor and automatically adjust the wiper speed and frequency based on the data provided by the rain sensor, thereby ensuring that the driver has a good view in all weather conditions.

3. Power Windows, Rearview Mirrors and Sunroof

The operation of power windows and rearview mirrors also requires the support of automotive PCB. Automotive PCB controls the motors and sensors to enable the electric doors and windows to achieve one-touch lifting and lowering functions, while the rearview mirrors can achieve functions such as electric folding, angle adjustment, heating and defrosting. These features not only improve the convenience of the vehicle, but also enhance driving safety.

In addition, the operation of the sunroof is also controlled by automotive PCB. Whether it involves the opening and closing of the sunroof, angle adjustment, or the automatic opening and closing of the sunshade, automotive PCB can ensure the stable operation of these functions, thereby providing users with more lighting and ventilation options in the car.

To sum up, the role of automotive PCB in automobiles is indispensable. By supporting multiple functions such as door control, seat adjustment, lighting system, wiper control, power windows, rearview mirrors and sunroofs, automotive PCBs greatly improve user comfort and convenience. With the continuous advancement of technology, automotive PCBs will continue to play an important role in improving driving experience and ride comfort, bringing users a more intelligent and humanized driving experience.

HoYoGo is an international, professional and reliable automotive PCB manufacturer, with high level automation and dedicated automotive production lines, with our automotive PCB accounts for 45% of our production. Our production strictly follows the high quality system and has passed ISO9001, ISO14001, ISO13485 and TS16949 certifications. All products strictly follow the IPC-A-600-H and IPC-6012 acceptance standards. If you have any related PCB requirements, please send us your inquiries.

评论

发表评论