What are the Characteristics of Glass Base PCB

Glass base PCB is a printed circuit board with glass material as the substrate. It has unique characteristics and shows obvious advantages in some high-end electronic application areas. So, what are the characteristics of glass base PCB?

1. High Dielectric Strength and Low Loss

The dielectric constant of glass material is relatively low. This characteristic shows that glass base PCB can significantly reduce signal loss and improve signal integrity during high-speed signal transmission. In fields such as communications, radar, and high-frequency equipment, a low dielectric constant helps ensure fast and stable signal transmission, reducing delays and errors during data transfer.

2. Excellent Thermal Stability

Compared with FR4 and ceramic substrates, glass substrates have a better coefficient of thermal expansion (CTE), that is, their size change less when the temperature changes, showing good dimensional stability. This characteristic makes glass substrates an excellent choice for high-temperature environments, such as power modules and optoelectronic devices in electric vehicles.

3. Stronger Thermal Management Capabilities

Because glass material has a relatively high thermal conductivity, it can quickly conduct away the heat generated during the operation of electronic equipment. This characteristic is particularly critical for high-power devices that need to dispose of large amounts of heat, such as power amplifiers and lasers.

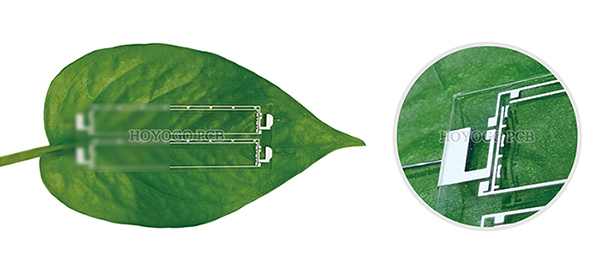

4. Optical Transparency

The optical transparency of glass substrates has significant application value in optoelectronics, optical sensors and display technologies. Transparent PCB allows light to pass through better and reduces the loss of optical signals. They are suitable for fields such as optical sensors, transparent displays and AR devices.

5. Strong Chemical Stability

Glass materials have high chemical inertness and can maintain stability in acid, alkali corrosion and other chemical erosion. This characteristic enables glass base PCB to achieve long-term stable operation in extreme environments, such as chemical, marine and other special industrial environments, thereby extending their service life.

6. Precision Manufacturing Capabilities

PCBs with glass substrates support higher density circuit designs. Due to the high surface flatness of the glass substrate, more delicate circuit patterns can be achieved, which helps to achieve miniaturization and high-density interconnection technology. This is critical for applications that require precision interconnects.

7. Electrical Insulation

The glass material itself has excellent electrical insulation properties, which enables it to effectively prevent accidental current leakage or short circuits of current in the circuit when used as a PCB substrate.

In addition, the application areas of glass base PCB is very wide and is suitable for manufacturing many electronic devices, including but not limited to optoelectronic devices, automotive electronics, medical equipment, servers, and personal computers.

HoYoGo is an international, professional and reliable glass base PCB factory. Our production strictly follows the high-quality system and has passed ISO9001, ISO14001, ISO13485, TS16949 and C-UL-S certifications. All products strictly follow the acceptance standard of IPC-A-600-H and IPC-6012. The quality of our products has been widely recognized by customers in Europe and America. If you have any related needs, you are welcome to send us an inquiry.

评论

发表评论