Technical Features of Underwater Light PCB

As the core component of underwater light devices, the technical features of underwater light PCB need to be fully adapted to the complex underwater environment. It must not only ensure the stable operation of the circuit, but also have excellent waterproof and anti-corrosion properties. The specific technical features are as follows:

1. Application of Special Materials

In order to adapt to the humid and high-pressure environment underwater, the material selection of underwater light PCB is very particular. In addition to the high thermal conductivity aluminum substrate, the PCB substrate will also use special material with excellent moisture resistance and corrosion resistance. These materials are able to maintain stable electrical performance in long-term underwater environments, preventing circuit failures due to moisture or corrosion.

For example, some PCB substrates made of special epoxy resins materials have good insulation properties and chemical corrosion resistance, and can effectively resist the erosion of seawater. During the PCB manufacturing process, special solder mask inks are also applied. These not only provide good insulation properties, but also can enhance the waterproof and anti-fouling capabilities of the PCB surface, further improving the reliability of the PCB.

2. Precision Circuit Design

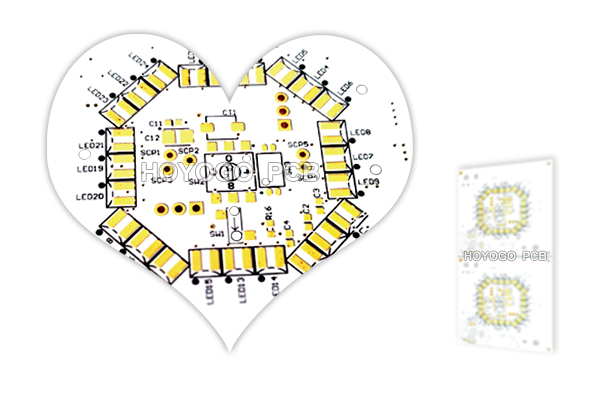

The functions of underwater lights are become more and more diverse, and the requirements for PCB circuit design are also getting higher and higher. In order to achieve precise lighting control, efficient power management and stable signal transmission, many factors need to be considered in PCB circuit design. For example, when designing LED driver circuits, the characteristics and quantity of LEDs must be taken into account to select suitable driver chips and circuit topologies. This ensures that the LEDs can obtain stable current and voltage and achieve uniform and bright lighting effects.

At the same time, to meet diverse requirement for lighting color and brightness adjustment in different scenarios, the circuit design integrates complex dimming and color control modules, enabling precise lighting control through technologies such as PWM (Pulse Width Modulation). In addition, to enhance the anti-interference capability of underwater lights, the PCB circuit design incorporates a series of electromagnetic compatibility (EMC) measures, such as optimized circuit layout and the addition of filtering circuits, to ensure stable operation in complex electromagnetic environments.

3. Strict Manufacturing Process

The manufacturing process of underwater light PCB directly affects its performance and quality. Due to the high reliability requirements of underwater lighting, PCB manufacturing process must follow strict process standards. From PCB design and PCB making, circuit etching, component mounting to the final testing and packaging, every step needs to be precisely controlled.

During the production process, the accuracy and clarity of the circuit must be ensured to avoid problems such as short circuit and open circuit. In the component placement stage, high-precision SMT(Surface Mount Technology) equipment is used to ensure that electronic components are accurately and securely soldered onto the PCB. At the same time, the welding temperature and time must be strictly controlled during the welding process to prevent component damage due to overheating. Finally, the manufactured PCB is subjected to comprehensive electrical performance tests and waterproof performance tests. Only PCBs that pass the rigorous tests can be used in the production of underwater lights, ensuring that each underwater light can work stably and reliably in the underwater environment.

HoYoGo is an international, professional and reliable underwater light PCB manufacturer. Professionalism creates quality. As a powerful manufacturer deeply engaged in the field of underwater light PCB, we strive for excellence in quality control. From raw material sourcing to finished product delivery, each PCB goes through over 10 strict quality checks to guarantee outstanding waterproof performance, easily handling complex underwater environment. If you have any related needs, welcome to send us your inquiries.

评论

发表评论